manipulator robotics automatic polishing machine for stainless

steel

I. APPLICAITONS:

1. Faucets

2. Auto spare parts

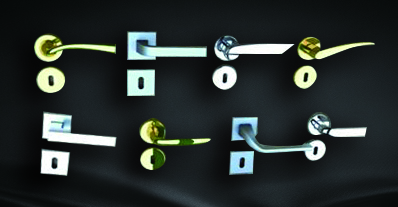

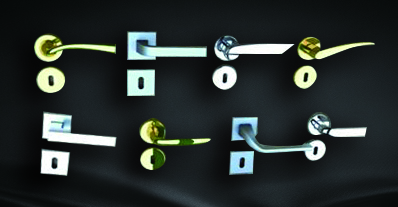

3. Locks and door handles

4. All kids of metals and jewelry accessory

5. Size range of polishing productsΦ 280*280

2.1 Product feature:

2.2.1The automatic polishing machine is an exclusive polishing

system consisting 4 manipulators with of 6 axises rotary; Multiple

stations simultaneous operation high flexibility and high product

efficiency.

2.2.2 The control system adopts PROMAX motion control technology

from Italy,stable propeert,high control accracy.

2.2.3 Software: Programmable, with protable handed device, contains

manually mode to simulate the workmanship polishing and record the

track; automatically operating model is available with pre-settled

parameters program.

2.2.4 Polishing pressure and wear compensation control performance:

When the polishing cloth wheel is worn out, the system can detect

that the torque becomes smaller and automatically the compensation

in all direction

2.2.5 Linear speed compensation: When the outer diameter of the

cloth wheel is reduced, the system automatically increases the

speed and compensation;

2.2.6Program setting of add polishing wax:free setting of wax

spraying time and frequency according to the characteristics of

product.choice of slid wax or liquid wax

2.2.7Full digital control, Can store 50 programs.Programs can be

saved and invoked at any time.

2.2.8 CN/EN language display on Touch Panel. to set all parameters

for an easy operation;fault codes display and alarm pages for quick

troubles shooting and repair.

2.3 TECHNICAL PARAMETERS

No. | Item | Parameters |

1 | Dimensions (L*W*H) | 5000*3400*3000(L*W*H) |

2 | Machine Power | 35KW |

3 | Rated Voltage | 380V |

4 | Max. Diameter of polishing wheel | 600mm |

5 | Min. Diameter of polishing wheel | 400mm |

6 | X-Axis travel (mm) | 1200 |

7 | Y-Axis travel (mm) | 1100 |

8 | Z-Axis travel (mm) | 700 |

9 | U-Axis travel (mm) | ±90° |

10 | V-Axis travel (mm) | ±360° |

11 | W-Axis travel (mm) | ±360° |

2.4 BASIC EQUIPMENT

No. | Device name | Brand | Remark |

1 | Motion control system | PROMAX Italy |

|

2 | Servo motor | PROMAX Italy |

|

3 | Variable frequency compensation system+Control card | AELTA |

|

4 | Cloth wheel motor spindle | SIEMENS | · |

5 | Main low voltage electrical | SCHNEIDER |

|

6 | Linear guide rail and screw | HIWIN | · |

7 | Reduction box | Rossi Italy |

|

8 | Bearing | NSK |

|

9 | Steering gear of fixture | TAIWAN | |

III Warranty:1 YEAR

IV After-sales service

Under warranty:

4.1 DZ warrants that under normal circumstances,upon receiptof the

notification of the customer’s after-sales service requirments(with

fault description attached),DZ will respond to the equipment

failure,diagnosis and troubleshooting within 4 hours by phone,fax

or e-mail.

4.2

4.2.1 DZ shall be responsible for probiding after-sales service

free of charge within the warranty period.

4.2.2 Within the warranty period, DZ shall be respond within 4

hours upon receiving the notice from the user, and the seller's

personnel shall come to the site for maintenance within 12 hours

for problems that cannot be solved by the buyer.

4.2.3 Free repair or repacement of faulty parts within 5 working

days. During the training period in DZ's site, the end-user is

responsible for all their engineer’s daily expense. 4.2.3 During

the traning period in the end-user's site, the end-user is

reponsible for DZ technician's daily accommodation.

4.3 Under warranty the above services and vulnerable parts free

replacement.

V TRAINING SERVICE

5.1 DZ provides training service to the end-user in different

stages: the equipment’s operation, Maintenance and Upgrades.

5.2

5.2.1 The buyer must cooperate with training

5.2.2 The buyer master the basic principle and debugging method of

equipment through training,have the ability to

use,maintain,operation and fault handling. Ability to modify,

develop, and improve processes and equipment as required.

| No.of trainers | arranged by buyer |

| Training time limit | < 3 days | Place for training | DZ’s factory |

| Training content | 1. Systen design principle 2. Principle of mechanical control 3. Operation procedure 4. Maintenance of equipment 5. Safety knowledge |