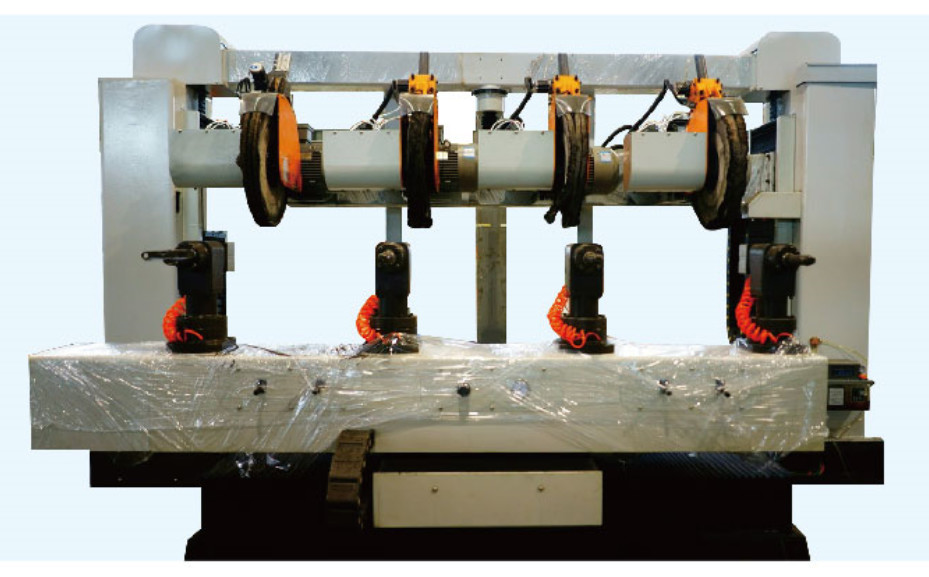

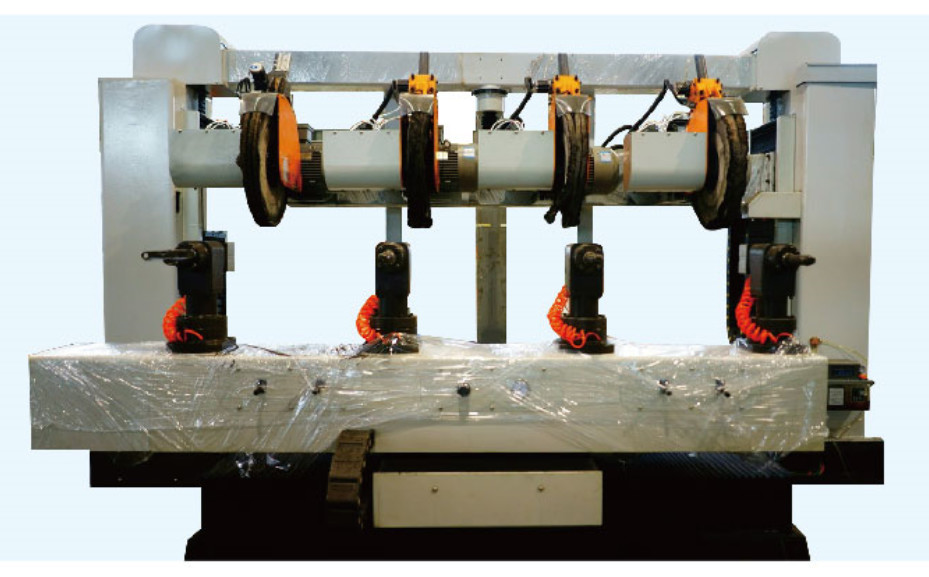

CNC Polishing Machine With Multiple Stations' Simultaneous

Operations For Door Handles Or Faucet

Ⅰ CHARACTERISTIC

- Uniform polishing quality without deformation of the processed

parts.

- High production. Four working stations work simultaneously, and

with one-time programming, the machine can finish the polishing and

buffing jobs of four workpieces at one time.

- Full auto, waxing system;

- Quick replacement of the fixtures.

- Quick replacement of the polishing mops.

- Cost-reduction in the number of fixtures.

- Important reduction in mops and polishing compounds consumption.

- Polishing system avoiding excessive temperature of the parts

during the working process.

- Quick and easy programming. Interactive Teach System.

- Finish the polishing/buffing jobs in any angle and position;

- High profitability and amortization. One single operator can

handle several machines by synchronizing the working cycles.

Ⅱ TECHNICAL PARAMETERS

| Code | Item | Specifications |

| 1 | Dimensions (L*W*H) | 4400*3400*2900 |

| 2 | Machine Power | 35KW |

| 3 | Rated Voltage | 380V |

| 4 | Max. Diameter of polishing wheel | 600mm |

| 5 | Min. Diameter of polishing wheel | 400mm |

Ⅲ Features of various polishing machines on the market

No

| project | DingZhu polishing machine | Robotic polishing machine | Special polishing machine | Remarks |

| 1 | quality | high | medium | low | |

| 2 | flexibility | Universal Angle, ensure that not deformation does not leakage | Universal Angle, ensure that not deformation does not leakage

| Easy to deformation and leakage

| |

3

| Wheel flexibility

| The wheel is large to ensure the line speed and the wheel is

flexible

| The wheel is large to ensure the line speed and the wheel is

flexible | The wheels are small and not very flexible enough

| |

| 4 | rigidity | Good steel, the wheels can be pressed tightly and polished

| Arms are too long, with poor steel performance | Good steel, the wheels can be pressed tightly and polished | |

| 5 | productivity | high | low | higher | |

6

| Add wax

| Solid wax, uniform, economical, and environmentally friendly | Liquid wax has a high cost, poor effect, and pollutes the equipment

and the environment | Liquid wax has a high cost, poor effect, and pollutes the equipment

and the environment | |

| 7 | Wheel loss | low | low | high | |

8

| self-compensating | Coordinate and line speed compensation effect is good | Without this function, it affects the quality | Without this function, it affects the quality | |

9

| frock

| Small quantity, simple structure, low cost | Small quantity, simple structure, low cost | The number is very large, complex structure, high cost | |

| 10 | Programming time | Within 2 hours | 8 Hours | 8 Hours | |

11

| Programming difficulty | Simple | Complicated | Complicated | |

12

| Change the product

| 15 Minutes | 2 Hours | 8 Hours | Previous production procedures exist |

| 13 | safety | high | medium | low | |

FAQ

Q1. Where is your factory located ? How can I visit it ?

A : Our factory is located in Quanzhou city,Fujian province,China.

You can fly to Jinjiang or Xiamen air port, we will pick you up.

Q2. Are you produce polishing machine's specific parameters

according to the samples?

A: Yes, we produce the machine you want by your samples or

technical drawings. Usually one machine have different molds and

fixtures like metal polishing machine,die casting machine.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if

we have ready machine in stock, but the customers have to pay the

sample shipping cost.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our

customers benefit ;

2. We respect every customer as our friend and we sincerely do

business and make friends with them, no matter where they come

from.